In a rapidly changing global electronics industry, LED packaging is at the heart of innovations that enable more efficient, reliable, and intelligent lighting systems. For B2B customers — from OEMs to contract manufacturers — and engineering professionals who specify LED components, understanding these trends is critical to designing products that meet today’s technical, regulatory, and market demands.

What is LED Packaging and Why Does It Matter?

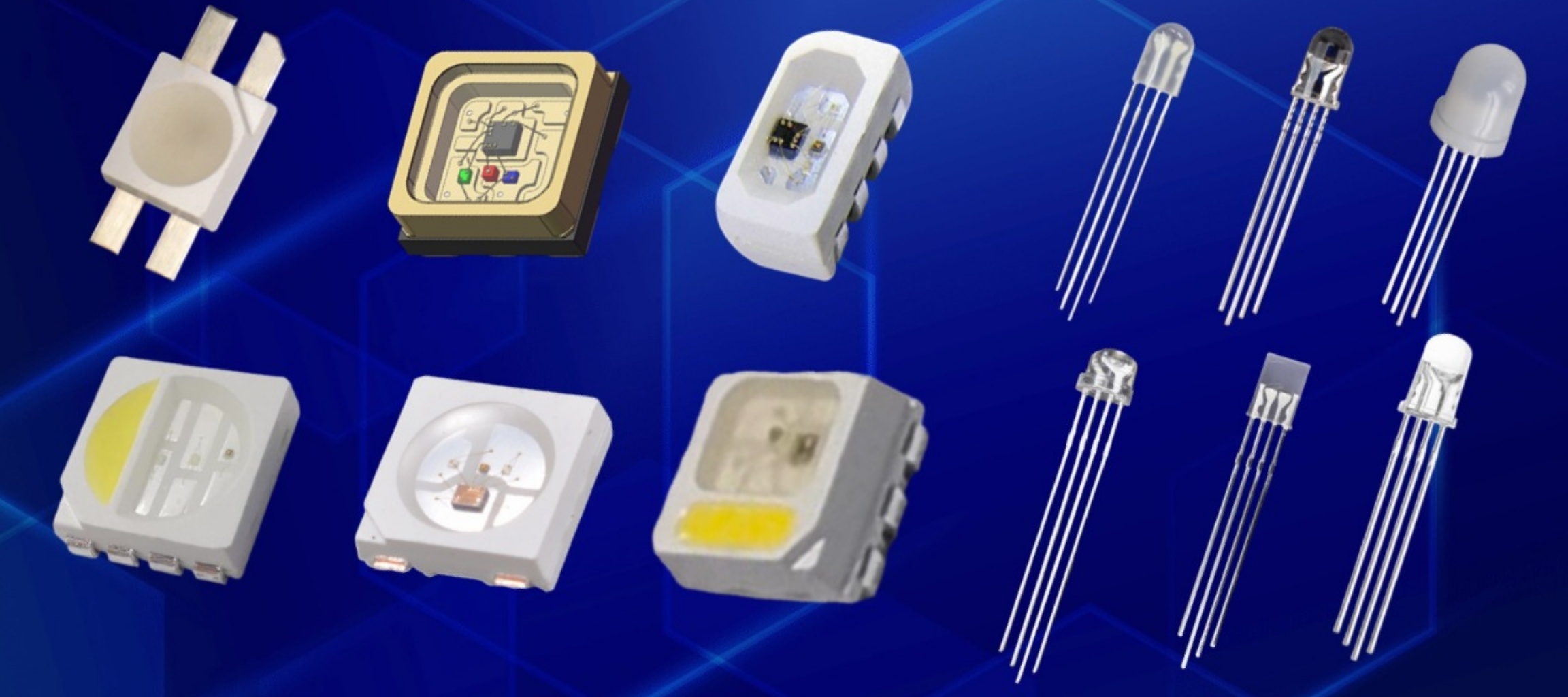

LED packaging refers to the comprehensive engineering process of encapsulating LED dies, ensuring mechanical protection, electrical connectivity, thermal stability, and consistent optical performance. As LEDs move beyond simple indicator lights toward complex, multifunctional systems, packaging becomes a crucial determinant of product lifetime, color stability, and thermal resistance.

Key roles of LED packaging include:

- Protecting sensitive semiconductor dies from moisture and mechanical shock

- Managing heat through thermal interfaces and high-conductivity substrates

- Optimizing light output via primary or secondary optics

- Enabling surface-mount compatibility and automated assembly

- Ensuring compliance with safety, RoHS, and other global standards

Technical Trends Impacting LED Packaging

1. Miniaturization and Advanced Interconnects

Driven by shrinking form factors in automotive, medical, and IoT markets, LED packages are moving from traditional leadframe-based SMDs toward CSP (Chip Scale Package) and flip-chip configurations. These approaches reduce thermal resistance, allow higher drive currents, and simplify integration into densely populated PCBs.

2. Enhanced Thermal Pathways

Thermal management remains a bottleneck for high-power LEDs. Packaging innovations now include:

Aluminum nitride (AlN) or silicon carbide (SiC) ceramic substrates

Metal-core PCBs with advanced thermal vias

Thermal interface materials with low outgassing for harsh environments

These solutions extend product life while maintaining color stability even under elevated temperatures.

3. Integrated Optical Control

For professional lighting and displays, consistent color coordinates and controlled beam angles are essential. Advanced packaging integrates micro-lens arrays, conformal phosphor coatings, or remote phosphor structures to achieve high CRI and stable chromaticity over the LED’s lifetime.

4. Functional Integration

LED packages increasingly embed functionality beyond illumination:

PIR or occupancy sensors

Ambient light sensing

Wireless radio modules (Bluetooth, Zigbee, Thread)

This trend supports the transition to smart lighting, where a single LED module can act as both a light source and a connected IoT node.

5. Spectral Expansion

Packaging technology is evolving to handle UV (ultraviolet) and IR (infrared) wavelengths for specialized markets including sterilization, spectroscopy, medical sensing, and facial recognition. UV packages must address photodegradation, while IR packages need superior thermal cycling resistance — both requiring specialized encapsulants and optics.

6. Sustainability and Compliance

Beyond technical performance, B2B customers increasingly require RoHS, halogen-free, and even carbon-neutral production. Advanced LED packaging addresses this with recyclable plastics, lead-free solder materials, and low-carbon manufacturing practices.

How Can B2B Partners Stay Competitive?

If you are an engineering team leader or sourcing manager, consider these points:

Audit your suppliers for packaging technology maturity and quality management

Collaborate early in the design phase for co-engineering of thermal, optical, and electrical characteristics

Validate suppliers’ RoHS and sustainability certifications

Invest in long-term partnerships to ensure stable supply and technical support

We actively track and invest in these industry-defining LED packaging trends. Our team supports B2B partners with in-depth technical knowledge, stable and scalable production capacity, and strict quality assurance protocols. Whether you are developing advanced lighting modules, sensors, or integrated smart devices, we can help you deliver reliable and competitive solutions.

Contact us today to discuss how our LED packaging expertise can accelerate your next project.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!